The inventory-to-sales ratio measures a business’s operational efficiency in inventory management.

It indicates how well a company is managing its inventory in relation to the sales it is making, revealing the balance between supply and demand.

By assessing this ratio, businesses can determine whether they’re carrying excess stock, which ties up capital and potentially increases storage costs, or if they have too little, which could lead to stockouts and lost sales.

Calculating this ratio involves comparing a company’s inventory cost against its sales over a certain period. A low inventory-to-sales ratio may suggest that a company is efficiently turning over its inventory, or it might indicate inadequate inventory levels that could fail to meet customer demand.

On the other hand, a high ratio could mean that inventory is not being sold as quickly, which can be a warning sign of overstocking or declining sales. Understanding and effectively managing this ratio helps companies to optimize inventory levels, reduce carrying costs, and enhance profitability.

Key Takeaways

- The inventory-to-sales ratio is essential for measuring the effectiveness of a company’s inventory management.

- A high ratio can indicate excess inventory, while a low ratio might suggest efficient turnover or insufficient stock.

- Effective management of this ratio is crucial for optimizing inventory levels and improving a company’s financial health.

Understanding Inventory to Sales Ratio

Inventory to Sales Ratio is a crucial financial metric indicating the relationship between a company’s inventory and sales volume. It sheds light on the efficiency of inventory management and plays a significant role in assessing performance against industry benchmarks.

Definition and Significance

Inventory to Sales Ratio illustrates how well a business manages its inventory and the demand for its products. The ratio indicates whether a company may be overstocking inventory or, conversely, if it could be at risk of stockouts. A balanced ratio suggests a company has enough inventory to meet demand without bearing excessive inventory costs.

Calculating Inventory to Sales Ratio

The formula for the inventory-to-sales ratio is:

Inventory to Sales Ratio = (Average Inventory ÷ Net Sales) x 100.

To calculate the average inventory, add the period’s beginning and ending inventory balances together and divide by two. Net sales can be found on the income statement.

Example:

If a company’s average annual inventory is $100,000 and its net sales are $500,000, the inventory-to-sales ratio would be (100,000 ÷ 500,000) x 100 = 20%.

Interpreting the Results

A low ratio indicates that a company may not have enough inventory to meet demand. This could result in lost sales opportunities and dissatisfied customers. On the other hand, a high ratio suggests that a company.

Here, inventory refers to the average inventory for a period, and Net Sales reflects the sales volume. This ratio can be assessed over different time frames to understand short or long-term trends.

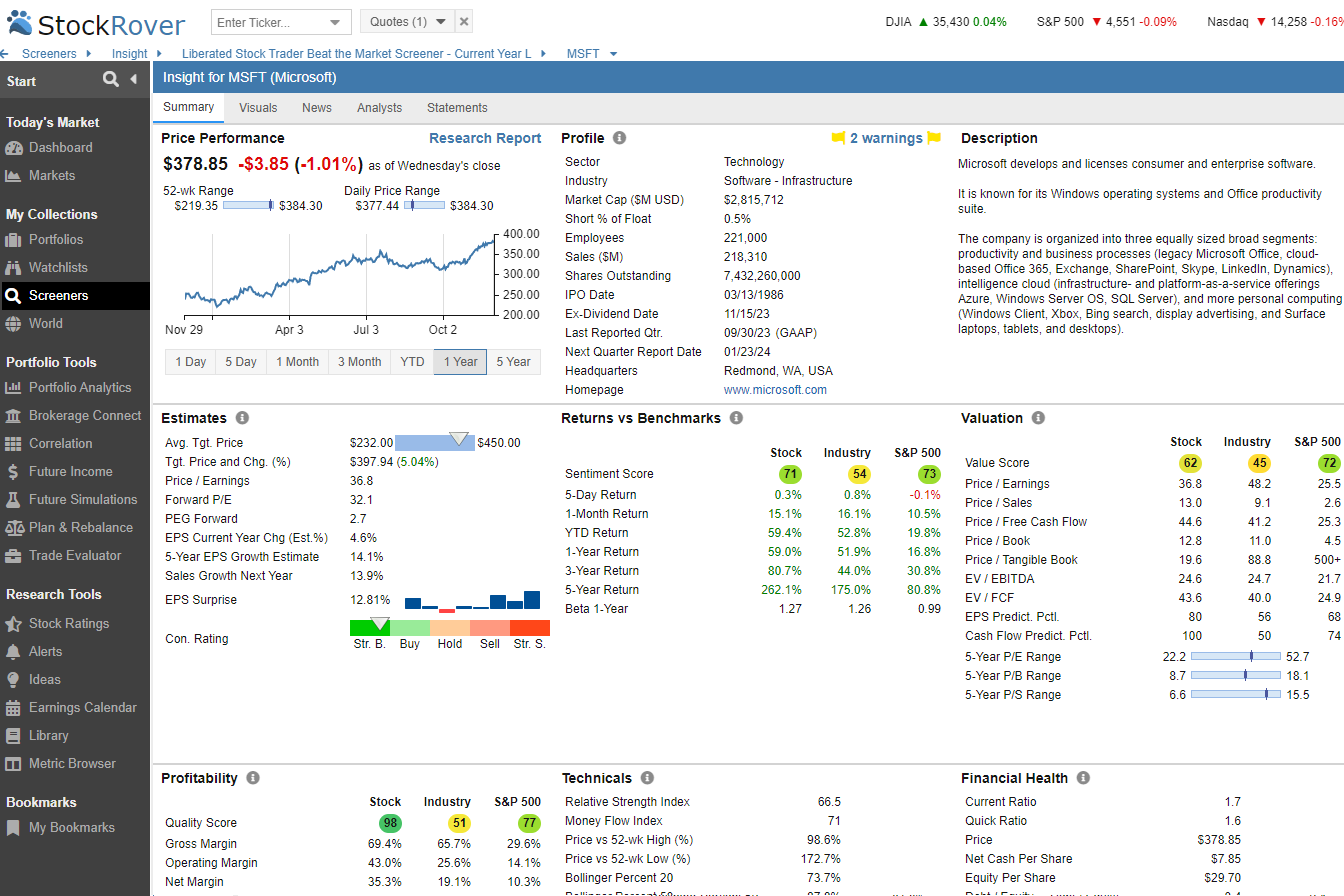

Try Powerful Financial Analysis & Research with Stock Rover

Inventory to Sales Ratio Interpretation

Analysts use the inventory-to-sales ratio to determine a company’s efficiency in converting stock into sales. A lower ratio implies that inventory is sold quickly, often corresponding to high demand or efficient sales strategies. Conversely, a higher ratio may signal overstocking, which could tie up capital unnecessarily and increase storage costs.

Inventory Turns and DSI

The turnover ratio, or Inventory Turns, shows how many times inventory is sold over a certain period. It is calculated by dividing the cost of goods sold (COGS) by the average inventory. On the other hand, days Sales of Inventory (DSI) indicates the average time in days that a company’s inventory is held before being sold. These indicators provide a comprehensive view of inventory efficiency alongside the inventory-to-sales ratio.

Inventory Management Fundamentals

Maintaining optimal inventory levels is crucial to operational efficiency in managing a supply chain. The right balance minimizes costs while ensuring product availability.

Inventory Levels and Their Impact

Inventory levels are the backbone of inventory management, influencing both stock availability and the supply chain’s financial health. Keeping inventory levels too low risks stockouts, disappointing customers, and potentially damaging relationships. On the other hand, excessive inventory can result in overstocked products, higher holding costs, and wastage. Businesses must analyze their inventory turnover to prevent both scenarios.

Role of Forecasting in Inventory

Effective forecasting is integral to inventory management. Utilizing demand forecasting, companies predict customer demand and adjust their inventory accordingly. This includes analyzing past sales data, market trends, and seasonality to anticipate upcoming needs. Inaccurate forecasting can lead to understocking or overstocking, illustrating why sophisticated forecasting tools are now essential for modern inventory management.

Importance of Efficient Stock Management

Efficient stock management is a critical aspect of a well-functioning supply chain. It encompasses tracking and controlling inventory from purchase to sale. Achieving this means businesses can minimize holding costs and maximize sales value. By implementing strategic stock management practices, such as just-in-time inventory, businesses can significantly improve their operational efficiency and responsiveness to market changes.

Strategic Considerations

Understanding the inventory-to-sales ratio is essential for maintaining a balanced operation. Two critical areas for strategic consideration involve looking at benchmarks within one’s industry and managing the relationship between available capital and inventory levels.

Industry Benchmarking

In evaluating their inventory effectiveness, businesses must consider industry benchmarks to understand how their inventory-to-sales ratio compares with competitors. These benchmarks can offer valuable insights into the efficacy of inventory management practices. They indicate the typical turnover a company within a specific industry may aim for. For instance, a higher ratio might suggest potential issues with overstocking, which could erode profit margin through increased storage costs or spoilage.

Balancing Capital and Inventory

Companies that effectively balance capital and inventory manage to tie up the least amount of capital in inventory without sacrificing their ability to meet customer demand. Capital tied up in excess inventory restricts a company’s agility and can result in lost opportunities elsewhere. Conversely, too little inventory can lead to stockouts, backorders, and lost sales. This is where precise budget allocation becomes crucial. By monitoring and adjusting inventory levels continuously, a company ensures that the capital invested in stock directly contributes to generating revenues and maintaining desired profit margins.

Challenges and Solutions in Inventory Management

Effective inventory management is essential for maintaining the delicate balance between excess inventory and stockouts. Companies strive to optimize this balance, facing ongoing challenges in supply chain fluctuations and the need for technological advancement to enhance visibility and performance.

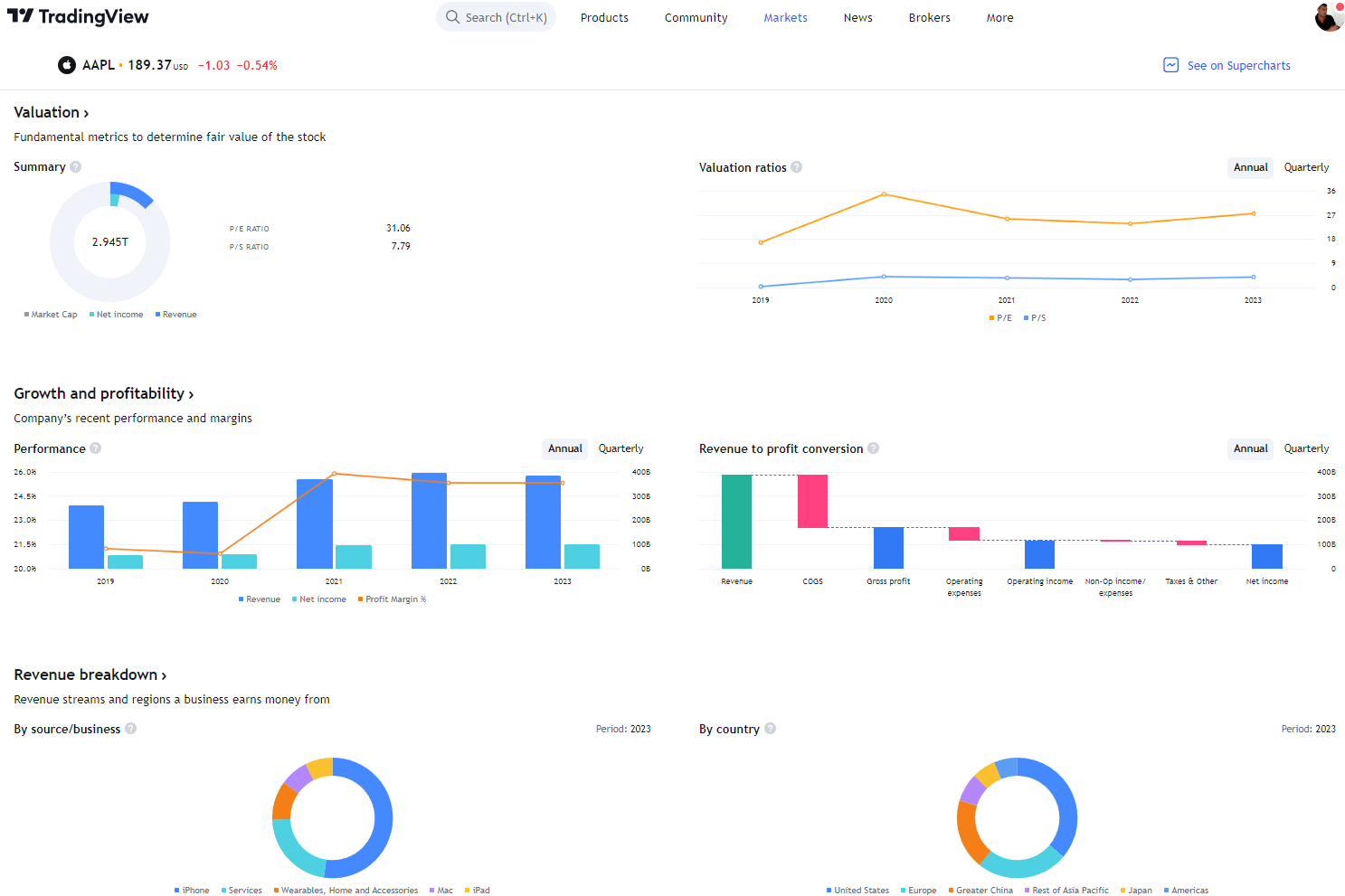

Try TradingView, Our Recommended Tool for International Traders

Global Community, Charts, Screening, Analysis & Broker Integration

Global Financial Analysis for Free on TradingView

Addressing Overstock and Stockouts

Overstocking leads to unnecessary capital tied up in excess inventory, risk of obsolescence, and high holding costs. Conversely, stockouts can result in missed sales opportunities and tarnished customer relationships. A multi-faceted approach to this includes:

- Safety Stock: Carefully calculated safety stock levels ensure a buffer against demand variability.

- Inventory Planning: Advanced inventory management strategies, such as Just-In-Time (JIT), curtail overstock situations by aligning inventory levels closely with demand patterns.

Adapting to Supply Chain Fluctuations

The current economic conditions highlight the need for responsive supply chain strategies. When suppliers face disruptions, businesses must have processes to adapt swiftly.

- Diverse Supplier Networks: Having multiple suppliers prevents reliance on a single source, minimizing risk.

- Real-Time Monitoring: Continuous monitoring of supply chain activities allows for prompt identification and resolution of potential disruptions.

Leveraging Technology for Better Performance

Investing in the right technology is pivotal for gaining in-depth visibility into inventory and enhancing overall supply chain performance.

- Inventory Management Software: Integrated systems track inventory in real-time, offering actionable insights to manage inventory turnover effectively.

- Data Analytics: Analyzing sales data aids in predicting future trends, enabling more precise inventory forecasting and reduction of obsolete stock.

By embracing these strategies, businesses can mitigate the risks associated with inventory management and supply chain disruptions, ensuring better preparedness for varying economic conditions.

Optimizing for Performance and Profitability

Effective optimization of the inventory-to-sales ratio can lead to substantial improvements in both performance and profitability. By carefully analyzing and adjusting inventory value and cost of goods sold, businesses can strike a balance that enhances customer satisfaction while boosting revenue.

Inventory Valuation and Revenue

Inventory Valuation: Accurate inventory valuation is critical to understanding the cost of goods sold (COGS). The average inventory value can be calculated by adding the beginning and ending inventory values and dividing by two. When businesses have a precise figure for their inventory value, they can better calculate the inventory-to-sales ratio, which is instrumental in gauging the efficiency at which stock is converted into sales.

Revenue Enhancement: Integrating inventory valuation with total sales data allows a company to adjust its inventory to meet customer demand without overstocking, maximizing revenue. High inventory turnover indicates a healthy balance between inventory levels and sales value, while a lower turnover may suggest overstocking or underperformance in sales.

You want to be a successful stock investor but don’t know where to start.

Learning stock market investing on your own can be overwhelming. There’s so much information out there, and it’s hard to know what’s true and what’s not.

Liberated Stock Trader Pro Investing Course

Our pro investing classes are the perfect way to learn stock investing. You will learn everything you need to know about financial analysis, charts, stock screening, and portfolio building so you can start building wealth today.

★ 16 Hours of Video Lessons + eBook ★

★ Complete Financial Analysis Lessons ★

★ 6 Proven Investing Strategies ★

★ Professional Grade Stock Chart Analysis Classes ★

Reducing Costs and Enhancing Customer Satisfaction

Cost Reduction: Monitoring the holding cost, which is the cost of storing and managing inventory, helps identify opportunities to reduce expenses. Optimal stock levels minimize costs associated with excess inventory and mitigate the need for deep discounts to clear stock. By reducing these costs, there’s a direct improvement in profitability.

Customer Satisfaction: Rapidly adapting inventory to sales patterns ensures swift fulfillment of customer orders, which boosts customer satisfaction. Satisfied customers are more likely to return, which means repeat sales and enhanced revenue over time. Inventory optimization requires a balance: enough stock to satisfy demand but not so much that it leads to a marked-down surplus.

Businesses can optimize their inventory-to-sales ratio by methodically managing inventory valuation in relation to revenue and consciously reducing costs while ensuring customer satisfaction. This targeted approach can lead to a higher turnover rate, reduced wasted resources, and, ultimately, increased profitability.

Key Metrics and KPIs

Certain metrics stand out in inventory management for revealing a company’s financial health and efficiency of supply chain operations. These key performance indicators (KPIs) and financial metrics are crucial for gauging profitability and optimizing the flow of goods.

Financial Metrics for Inventory Management

Inventory Turnover Ratio:

This financial metric is paramount in assessing how many times inventory is sold or used over a period. A higher inventory turnover ratio indicates operational efficiency and could increase profitability. It is calculated by:

- Inventory Turnover Ratio = COGS / Average Inventory

Cost of Goods Sold (COGS):

COGS help understand the direct costs attributable to the production of the goods a company sells. This financial metric directly impacts the bottom line, as it is subtracted from revenues to determine gross profit:

- COGS = Beginning inventory + Purchases During the Period – Ending inventory

Supply Chain KPIs and Inventory

Stock Keeping Unit (SKU):

Tracking SKUs is vital for inventory management, allowing businesses to monitor individual product-level performance, which informs stocking decisions and operational efficiency.

Supply Chain KPIs:

These indicators reflect the holistic view of a supply chain’s performance. Metrics of note include:

- Order Accuracy Rate: Reflects the accuracy of fulfilling customer orders.

- Fill Rate: Measures the percentage of customer demand met without stockouts.

Business performance in this domain is hinged on effectively monitoring these KPIs, which can highlight areas that require attention or adjustment to maintain a competitive edge.

Conclusion

The inventory-to-sales ratio emerges as a critical metric for assessing a company’s ability to effectively manage its inventory levels in relation to its sales volume. Companies strive for a balanced inventory ratio: not too high to avoid excess carrying costs and not too low to prevent stockouts and customer service issues.

A lower inventory-to-sales ratio evidences efficient inventory management, implying that a company is adept at converting its inventory into sales and has a lean inventory system. Conversely, a higher ratio may indicate potential inefficiencies, signaling that a company carries too much inventory compared to its sales, which could tie up valuable capital and increase storage costs.

When implemented strategically, inventory management practices enhance business performance by:

- Reducing carrying costs: By maintaining optimal inventory levels, businesses minimize the expense associated with excess stock.

- Improving cash flow: A lower inventory-to-sales ratio generally suggests quicker inventory turnover, facilitating better cash flow management.

- Enhancing customer satisfaction: Sufficient stock levels ready for sale help meet customer demand promptly, leading to increased customer loyalty.

- Increasing profitability: Efficient stock management can lead to cost savings and higher profit margins due to the timely and appropriate allocation of resources.

Companies should routinely monitor this ratio and adjust their inventory strategies accordingly, aiming for a ratio that aligns with industry standards and market conditions.

FAQ

How does the inventory-to-sales ratio differ from inventory turnover?

The inventory-to-sales ratio measures the amount of inventory on hand compared to the sales volume in a given period, indicating how well inventory is being converted into sales. In contrast, inventory turnover calculates how often a company's stock is sold and replaced over a particular period, showing the rate at which inventory moves.

What implications does the inventory-to-sales ratio have for manufacturing companies?

For manufacturing companies, the inventory-to-sales ratio sheds light on production planning and inventory control. A low ratio often signifies that production is in line with demand, whereas a high ratio might imply overproduction or decreasing product demand.

How can the inventory-to-sales ratio indicate changes in the business cycle?

Changes in the inventory-to-sales ratio can reflect shifts in the business cycle. An increasing ratio may hint at economic slowdowns as businesses could accumulate unsold goods. In contrast, a decreasing ratio could suggest an upcoming period of economic growth with higher consumer demand and sales.

What is considered a healthy inventory-to-sales ratio in the retail sector?

A healthy inventory-to-sales ratio in the retail sector varies but typically falls below one, with an optimal range often between 1/6 and 1/4. Retailers aim for a lower ratio to reduce holding costs and maintain cash flow effectiveness.

Why might wholesale companies monitor their inventory-to-sales ratio differently than retail businesses?

Wholesale companies typically deal with higher volumes of inventory than retail businesses. They might monitor their inventory-to-sales ratio to align with fluctuating supply chain dynamics and bulk purchasing patterns, which might differ from the more direct sales patterns in retail.

What can a high inventory-to-sales ratio signify for a company's financial health?

A high inventory-to-sales ratio could signify potential issues such as excess stock, reduced demand, or ineffective sales strategies, all of which might be red flags indicating a need for corrective action regarding a company's financial health and inventory management.